Mining boots are specialised work boots designed to endure the very specific rigours and hazards of the mining industry. Built from high-performance materials, mining boots have been meticulously engineered to protect miners from falling objects, industrial machinery, uneven terrain, and various other workplace hazards of the mining industry.

This protection extends to miners as well as the numerous vocations that comprise the mining industry. From drillers, loaders, blasters and machine operators — to electricians, mechanics, surveyors and safety officers — everyone in this expansive industry benefits from the safety and protection offered by industrial mining boots. Indeed, even those who are not working in high-risk areas may still be struck by strains, sprains and muscular injuries if not equipped with appropriate safety boots.

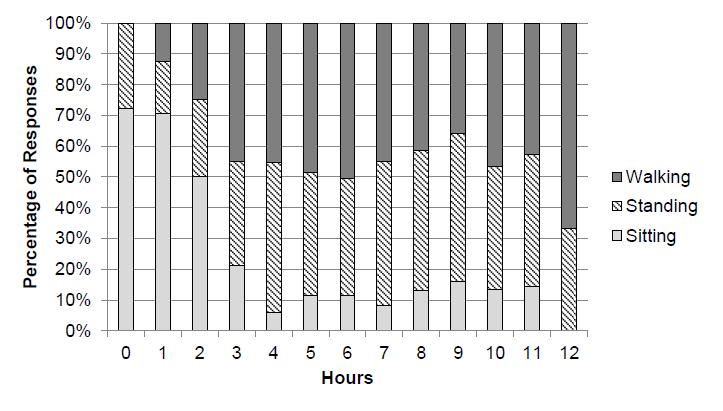

In 2017, a survey was conducted by the University of Wollongong on 358 coal miners in New South Wales. The figure below shows the number of hours participants in the survey said they spent walking, standing, and sitting during a typical 12 hours shift.

On average, workers in the mining industry spend the most time walking and standing. This can, of course, lead to exhaustion and injury if they are not equipped with footwear designed for comfort and support.

The Hazards Mining Workers Face

Workers in mines are exposed to a wide range of potential hazards on a daily basis. The appropriate safety boots can help mitigate many of these risks, optimising protection against dangers such as:

-

Sharp and Abrasive Rocks: A mine site harbours a multitude of sharp objects, including rock and mineral fragments, as well as metal debris, all of which pose risks of cuts, punctures and abrasions. Oliver’s AT 65 Series is equipped with Q-Flex® technology, a non-metallic insole that provides protection against penetration by sharp objects across the entire foot surface while ensuring maximum flexibility and comfort. Additionally, SAFETYcell® protection, a fully integrated protective shell, offers enhanced abrasion, impact, cut and chemical resistance for harsh working conditions.

-

Exposed Reinforcing: While exposed reinforcing provides crucial structural support in mines, it also presents significant foot injury hazards. Workers face injury risks such as punctures, lacerations and impalement from sharp edges, corrosion weakening structural integrity, protruding bars, and entanglement in loose mesh. The Oliver AT 65 Series incorporates Q-Flex® non-metallic penetration protection insole and SAFETYcell® for all round foot protection. For metatarsal protection, the PORON® XRD™ Metatarsal Guard acts as a built-in shield, absorbing up to 90% of intense impact force.

-

Slippery or Low Traction Surfaces: Navigating a mine site is a constant battle against treacherous terrain. Uneven ground, slick rocks, mud-caked surfaces and loose gravel all create low-traction environments, making every step a potential slip hazard. Oliver Footwear offers excellent SRC-rated slip resistance, providing reliable grip and stability to keep workers safe while they navigate these hazards.

-

Hot and Cold Surfaces: Miners may encounter a range of hot and cold surfaces in their work environments, due to the varied and extreme conditions often found in mining operations. Surfaces are often heated from thermal vents, heavy machinery, or processed materials. Conversely, many mining site surfaces incur extreme colds, owing to underground tunnels or areas that are covered in puddles or ice. The Oliver AT 65 Series offer a heat resistance rating of 300°C to provide protection against direct contact with hot surfaces, preventing burns and other heat-related injuries. The AT 65 Series is also 100% waterproof and incorporates COOLstep® moisture-wicking lining to keep feet dry and comfortable for all-day wear.

-

Chemical Exposure: Mining sites often present significant risks of chemical exposure to workers. The process of extracting and processing minerals can release a variety of hazardous chemicals into the environment. Oliver’s AT 65 Series has S3 waterproof rating, and features the unique Oliver Waterproof System, engineered to draw moisture away from the foot and prevent water from penetrating the boot. The AT 65-493, 65-490 and 65-490Z are caustic resistant, capable of withstanding the corrosive effects of caustic substances over time.

-

Electrically Charged Objects: The mining industry is rife with electrical hazards associated with the high-voltage equipment used in drilling, excavation, and transportation, as well as the electrical installations used for lighting and communications. The ubiquity of these equipment pose a constant risk of electrical hazards and static build-up to workers, equipment, or processes. Explore the Oliver AT 65 Series, with Anti-static (A) rated and Electrical Hazard (EH) rated options for enhanced electrical safety to reduce static build-up and insulation protection.

Health Issues in Mining Workers That Stem from Poor Footwear

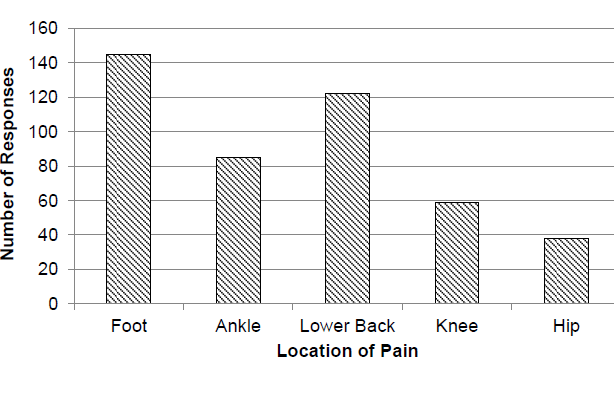

There are a slew of health problems common amongst mining workers that arise simply because they are wearing inadequate footwear at work. The University of Wollongong Coal Miners Survey determined the primary causes of injuries, by asking participants to identify which parts of their bodies experienced the most pain.

-

Foot Problems: A significant number of the recipients reported experiencing foot problems (55.3%), with the majority of this group (68.8%) indicating that their foot pain occurred “occasionally” to “often”. Foot pain was significantly more likely to be reported by participants who performed heavy lifting and worked on muddy and dirt surfaces.

-

Knee Pain: Remarkably, participants in supervisory roles were significantly more likely to experience knee pain.

-

Lower Back Pain: 44.5% of the participants reported some form of lower back pain.

-

Hip Pain: Research has shown that miners working on dirt surfaces were significantly more likely to have hip pain.

-

Ankle Pain - 57.9% of the miners who reported ankle pain said it was “occasional” to “often”.

No surprise, over half of those (62.3%) experiencing pain in their feet and/or ankles attributed their discomfort to the footwear they were using.

Mining Safety Boots Standards in Australia

The mining industries in Australia and New Zealand follow strict safety standards, with significant emphasis on the quality of foot protection and other safety gear. It is crucial that all industry stakeholders adhere to these safety standards to minimise risks effectively. Manufacturers of safety footwear are required to comply to the Australian Standard AS 2210.3:2019, which New Zealand typically refers to as well. This standard outlines design, construction, and safety performance requirements for protective footwear, encompassing protection against mechanical risks, slips and thermal hazards, to name a few. It applies to safety footwear for industrial use across Australasia, serving as a regulatory benchmark to ensure worker safety in industrial environments.

Oliver Footwear is certified to comply with the Australian Standard AS 2210.3:2019, offering miners superior protection with boots built to last longer and for all-day comfort.

The booming Australian mining industry has seen a surge in worker numbers, workplace hazards and consequently, the demand for high-quality work boots. Investing in quality industrial mining boots is crucial to ensure worker well-being and maximise workforce productivity.

The Oliver Mining Safety Boots Range

Oliver Footwear is Australia’s leading safety footwear manufacturer of high-quality mining boots. More than just safety performance, Oliver mining boots are engineered for resilience and all-day comfort to meet the needs of miners enduring long work shifts. Having collaborated with the mining industry, Oliver’s AT 65 Series work boots have swiftly become the safety footwear of choice for underground mining and drilling crews.

The wide selection of safety boots caters to a diverse range of styles, sizes and work requirements.