Buying the right work boots is the first step in keeping workers safe and reducing musculoskeletal problems. This footwear should meet Australian Standard AS 2210.3:2019 and have all the safety features relevant for your worksite. However, work boots don’t last forever. They experience wear, they get damaged, and they may eventually not offer the protection that workers rely on for their safety and health.

Proper usage and practical maintenance routines can significantly extend the lifespan of your work boots. They can also help you identify when boots need to be replaced.

Here is a helpful checklist:

Check and clean the tread

Check and clean the tread

Slip resistance comes from the ability of the boots to push liquids out from underneath the sole, thus keeping the tread in contact with the ground. Micro cleats grip on smooth internal surfaces while larger cleats provide stability in outdoor terrain. Debris that gets stuck in the cleats and tread prevents this from happening.

Cleaning the soles should be done after each working shift. Tread depth is also important. When the tread is worn down, there is no pathway for liquid to flow and this leads to slipping. The Oliver ST40 range features wear indicators that help identify sole wear and when replacement is due. Boots should be changed out for a new pair when the wear indicator becomes visible on the sole of the boots.

Brush and wipe the outside of boots

Brush and wipe the outside of boots

To clean your boots, remove any debris with a brush or wipe clean after use with a damp cloth. Ensure you allow wet boots to dry naturally at room temperature as artificial drying can cause leather to shrink, harden and crack. Removing contaminants extends the life of the boots by preventing damage to the material over time.

Polish full grain leather uppers

Polish full grain leather uppers

Full grain leather uppers should be polished or treated with commercially available leather polish. Oliver Footwear’s suede and nubuck leathers can be treated before wear with commercially available suede and nubuck protectors. This creates an invisible shield that helps prevent water and dirt from penetrating suede and nubuck footwear while still allowing them to breathe. If your suede or nubuck boots start to appear worn and flattened, gently scrub them with a clean toothbrush or towel. If it’s in bad shape, consider holding your boots above steam for a few seconds before brushing. Avoid using water to clean suede or nubuck, as it can affect both the colour and the texture.

Inspect for cuts, wear and tear

Inspect for cuts, wear and tear

The outer material of work boots may be compromised from impact with a sharp object or the wear and tear from constant use. If a steel toecap or metatarsal shield is exposed, it is time to replace the boots. Cuts or perforations in the upper material of work boots are also a serious safety concern. Their presence means that the boots have been compromised and do not offer the same protection as a new pair of boots.

This presents several risks to workers:

- Sharp objects falling on the boots could penetrate the weaker upper material and pierce a worker’s foot.

- Waterproofing is compromised. Once water enters the body of the boots through a cut in the outer material, it will soak into the boots. This makes the boot heavy and more difficult to walk.

Carrying out daily inspections of the integrity of the outer boots will identify these risks before an incident occurs.

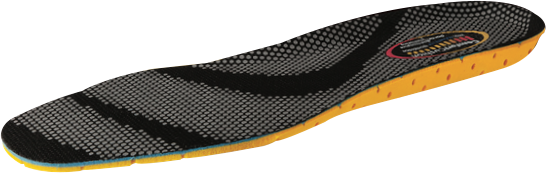

Inspect footbeds and check boot fitment

Inspect footbeds and check boot fitment

Footbeds provide comfort for different shapes of workers’ feet. As the footbeds wear down, the fitment of the boots may no longer be ideal. This creates friction inside the boots and can cause injury to the foot. Where visible signs of wear appear on footbeds, these must be replaced for worker comfort and safety.

Check the state of cushioning in the boots

Check the state of cushioning in the boots

Shock absorption comes from the structure of the heel, which provides some spring to the foot. The inner sole also provides cushioning and support to the toes for propulsion. All these elements are subject to wear from consistent daily use. It is advisable to check the condition of the shock absorption and inner sole on a weekly basis. An inner sole could be replaced without replacing the entire boot to prolong the life of the boots and maintain a high level of safety and comfort.

Check condition of laces and bindings

Check condition of laces and bindings

Broken laces or bindings increase the risk for injury more than one might think. The obvious result is a loose boot, which may slip on the foot while walking. Even worse is a slip while climbing, which could lead to a serious fall. Daily inspections on the condition of bindings and laces will identify problems so that they can be replaced before an incident happens.

Avoid extreme heat

Avoid extreme heat

Drying work boots using extreme heat is not advisable. Exposing work boots to extreme heat can compromise their material composition, making them unsafe for use, even if no visible damage is apparent. Boots should be dried naturally at room temperature as artificial drying can cause leather to shrink, harden and crack. Never store boots in direct sunlight or in damp environments.

Replace boots when struck by a heavy object

Replace boots when struck by a heavy object

Although the toe cap protection is designed to absorb a heavy blow, it is not wise to assume a work boot can be subjected to many blows without being compromised. It is advisable to change boots that have performed its protective function, rather than use it multiple times.

Use two pairs of boots and rotate them

Use two pairs of boots and rotate them

Feet sweat and cause moisture to build up inside work boots. Not only is this uncomfortable, but it can also do harm to the material over time. Rotating two pairs of boots gives time for evaporation in each boot and ensures that the build-up of sweat is minimal and does not cause safety or health issues

Having a routine maintenance task list will help to extend the lifespan of work boots as well as protect workers from unsafe conditions. While most workers want to quickly exit the workplace at the end of a shift, an extra five minutes of care for work boots and other personal protective equipment (PPE) may make the difference between safety and an injury on the next shift.

Having a routine maintenance task list will help to extend the lifespan of work boots as well as protect workers from unsafe conditions. While most workers want to quickly exit the workplace at the end of a shift, an extra five minutes of care for work boots and other personal protective equipment (PPE) may make the difference between safety and an injury on the next shift.